Introduction to Spezialbohrgetriebe

The term Spezialbohrgetriebe refers to specialized drilling gearboxes engineered for high-precision, high-performance applications. Unlike standard gear systems, these gearboxes are designed to handle extreme torque loads, operate under continuous stress, and deliver accuracy even in challenging industrial environments. They are the backbone of many advanced manufacturing processes, ensuring that drilling tasks are executed with pinpoint precision.

Over the years, gearbox technology has evolved significantly. What started as simple mechanical systems for torque conversion has now advanced into complex, highly efficient mechanisms integrated with electronic controls, noise reduction features, and smart sensors. The evolution of Spezialbohrgetriebe has mirrored the progress of industrial engineering, making them indispensable in sectors where precision and durability are critical.

Industries such as aerospace, automotive, construction, mining, and even fine watchmaking depend on Spezialbohrgetriebe. Their ability to maintain performance under extreme loads makes them a preferred choice for professionals who cannot compromise on accuracy. From micro-drilling in electronics to deep drilling in oil exploration, these gearboxes ensure smooth, stable, and efficient operation. As industrial requirements become more complex, the demand for such specialized gearboxes continues to grow.

2. Types of Spezialbohrgetriebe

There are several variations of Spezialbohrgetriebe, each designed for specific drilling tasks and operational environments.

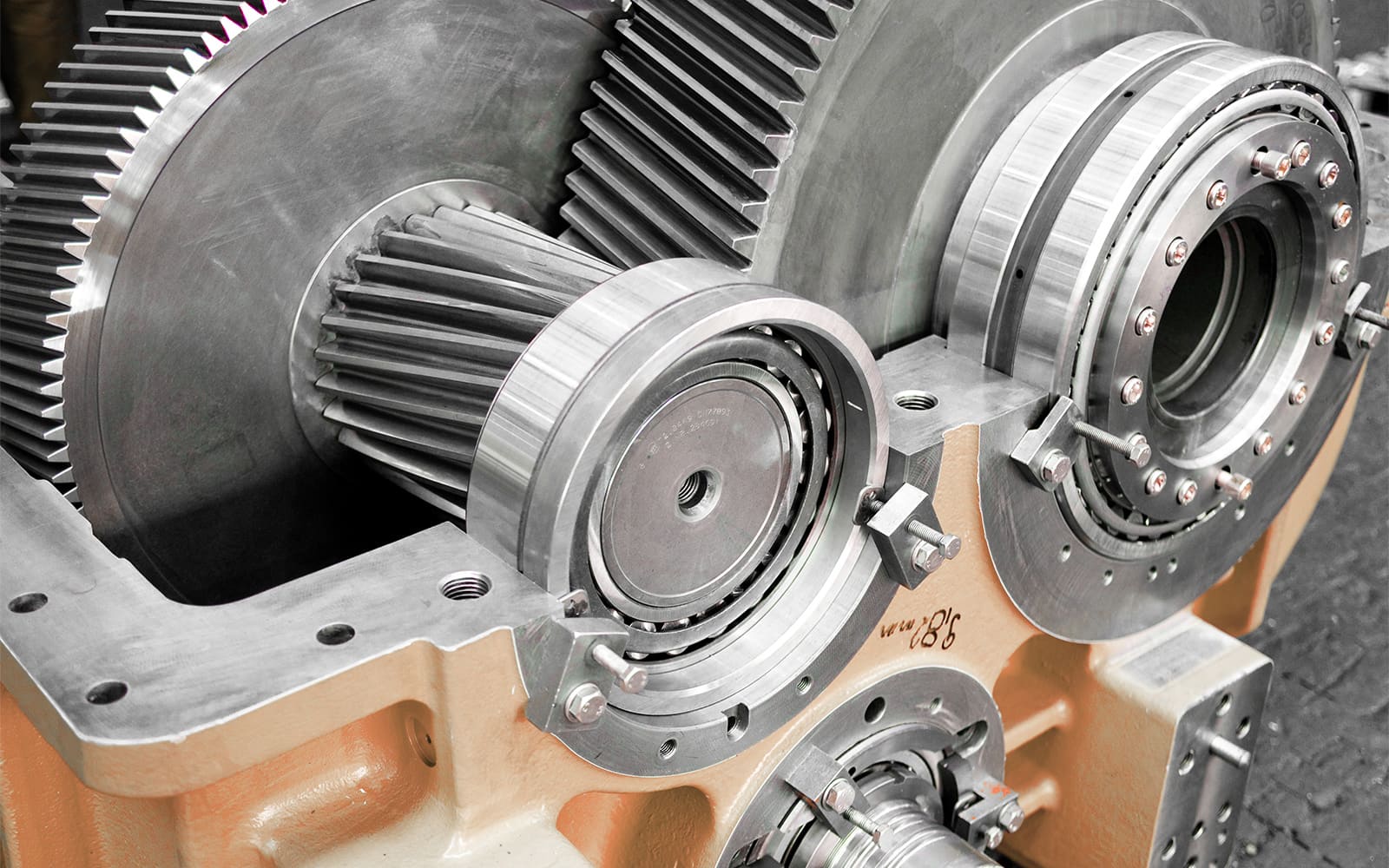

Planetary Spezialbohrgetriebe are compact, highly efficient systems where multiple gears rotate around a central sun gear. This arrangement allows for exceptional torque handling in a relatively small housing, making them ideal for high-load drilling applications.

Right-Angle Spezialbohrgetriebe are designed for operations where space is limited, and the drilling angle must be adjusted without compromising torque delivery. They are commonly used in confined industrial setups, construction sites, and shipbuilding.

Custom-Built Spezialbohrgetriebe are tailored for unique industrial requirements. Manufacturers can design these gearboxes with specific gear ratios, casing materials, lubrication systems, and mounting configurations to suit specialized projects.

The choice between these types depends on factors like operational load, space constraints, torque needs, and environmental conditions. Each type comes with its strengths, and selecting the right one ensures optimal performance and longevity.

Key Features and Technical Specifications

Spezialbohrgetriebe are distinguished by their advanced technical capabilities. Torque capacity is one of the most crucial specifications—higher torque ratings allow gearboxes to handle heavier loads without strain. Speed range is another essential factor, as certain applications require variable speeds for precision control.

Gear ratios determine how torque and speed are balanced. For example, a high gear ratio might offer more torque for deep drilling, while a lower ratio allows faster drilling speeds. Modern Spezialbohrgetriebe often include noise reduction systems and vibration dampers to improve operational comfort and extend equipment life.

Lubrication and cooling are vital for efficiency and durability. Some models feature automatic lubrication systems that minimize wear and tear, while others integrate cooling mechanisms to prevent overheating during continuous use. Wear-resistant materials such as hardened steel, composite alloys, and specialized coatings further enhance durability, ensuring that these gearboxes deliver consistent performance for years.

Applications of Spezialbohrgetriebe

The versatility of Spezialbohrgetriebe means they are used across multiple industries. In industrial manufacturing, they play a critical role in the automotive and aerospace sectors, where precise drilling of engine components and aircraft parts is required.

In construction and infrastructure projects, these gearboxes are integrated into heavy-duty drilling machines used for foundation work, bridge construction, and tunnel boring. Their ability to handle demanding loads and rough conditions makes them invaluable.

In precision engineering, such as medical device manufacturing and electronics production, miniature Spezialbohrgetriebe allow micro-drilling with exceptional accuracy. Even watchmakers rely on them for intricate gear assembly and drilling operations.

For the oil, gas, and mining industries, Spezialbohrgetriebe are indispensable in deep drilling operations, often working in harsh environments with extreme temperatures and pressures. Case studies show how companies have significantly improved productivity and reduced downtime by upgrading to specialized gearboxes.

Choosing the Right Spezialbohrgetriebe

Selecting the right gearbox requires a thorough assessment of operational needs. The first step is to determine the load requirements and the environmental conditions in which the gearbox will operate. For example, a gearbox used in a mining drill must withstand dust, heat, and vibration.

Matching the gearbox type to the application is critical. A planetary gearbox might be ideal for high-torque needs, while a right-angle version is better for compact spaces. Compatibility with existing machinery also plays a vital role—incorrect mounting or mismatched specifications can lead to costly inefficiencies.

Price is always a factor, but buyers should focus on value rather than the lowest cost. Investing in a high-quality Spezialbohrgetriebe often leads to lower long-term maintenance expenses and higher operational efficiency. Avoiding common mistakes—like choosing a gearbox based solely on torque ratings without considering speed and durability—can save both time and money.

Installation, Maintenance, and Troubleshooting

Proper installation is the foundation for optimal gearbox performance. Before installation, ensure that the mounting surfaces are clean, aligned, and free from defects. Follow manufacturer guidelines for torque settings, lubrication, and safety precautions.

Routine maintenance is essential to maximize lifespan. This includes regular lubrication, checking for gear wear, monitoring for unusual noises, and ensuring that seals are intact. Preventive maintenance schedules can significantly reduce the risk of sudden failures.

Troubleshooting common issues like overheating, misalignment, or vibration can prevent major damage. Overheating often indicates lubrication issues or excessive load, while vibration may be due to misalignment or worn gears. In some cases, repairs are cost-effective; in others, replacing the gearbox is the smarter choice.

. Market Trends and Innovations

The Spezialbohrgetriebe market is evolving rapidly. Manufacturers are introducing advanced materials like carbon-fiber-reinforced polymers for lightweight yet strong gearbox casings. Smart technology integration allows gearboxes to monitor performance in real time and send alerts for maintenance needs.

Sustainability trends are also shaping the industry. Eco-friendly lubricants and energy-efficient designs are becoming more common as companies aim to reduce environmental impact. The integration of Spezialbohrgetriebe into Industry 4.0 frameworks ensures that they remain relevant in a digital manufacturing era.

. Conclusion

Spezialbohrgetriebe represent the perfect blend of engineering precision, durability, and versatility. They are indispensable tools across industries, enabling operations that demand accuracy, power, and reliability. For buyers and engineers, focusing on the right specifications, proper installation, and regular maintenance ensures long-term success.

Also Read: awt88k meaning